Views: 0 Author: Site Editor Publish Time: 2025-08-28 Origin: Site

The primary purpose of dunnage bags is to keep cargo safe during transport. Dunnage bags fill empty spaces between items, preventing movement and damage. When you place a dunnage bag in a truck, railcar, or shipping container, it secures the load in place and stops items from sliding around. Many companies have seen a significant reduction in cargo damage after using dunnage bags, with damage rates dropping from 14% to less than 1%. This purpose not only protects your goods but also saves time and money with every shipment.

Dunnage bags help keep cargo safe. They fill empty spaces and stop things from moving during transport. Using the right size and inflating dunnage bags the right way stops damage. This also helps lower product loss. Dunnage bags do not cost much. They can be used again. They are light and strong. This makes shipping easier and saves money. Pick dunnage bags based on your cargo type. Also think about how you will move it and the weather. This gives the best results. Put dunnage bags in the right place and check them often. This helps make sure your cargo gets there safe and not broken.

You want your cargo to get there safely. Dunnage bags help by working like strong, air-filled cushions. When you put dunnage bags between boxes or pallets, they fill the spaces and make everything fit tightly. This stops your goods from moving inside trucks, railcars, or shipping containers.

Dunnage bags are light but very strong. They take in shocks and shakes during travel. This helps keep your cargo safe and steady. You can use them in trucks, railcars, or ships. Their main job is to keep your load still, even if the road is rough or the ship moves.

You can count on dunnage bags for good cargo control. They are simple to use and only need air to fill up. You can use them again for more than one trip. Check them before and after each trip to make sure they still work well.

Empty spaces between cargo can cause problems when moving. Dunnage bags fix this by filling gaps between pallets, crates, or other big items in containers. If you leave these spaces open, cargo can move or hit each other and get damaged.

Dunnage bags fill with air and can change shape. You can fit them into many sizes and shapes of spaces, so they work well for odd loads.

They make a wall between your cargo and the container sides, which stops things from moving.

By filling these spaces, dunnage bags help you ship better and lose less product.

When you use dunnage bags to fill spaces, you make sure every part of your container is used to keep things safe. This way is better and cheaper than using wood or foam blocks.

Cargo faces many forces like speeding up, stopping, or turning fast. Dunnage bags stop cargo from moving by making a tight block between items or between cargo and the container wall. It is important to fill the bag with the right amount of air. When you do, it works like a cushion and a brace to hold things in place.

Dunnage bags help stop cargo from sliding or tipping over. They take in bumps, rolls, or shakes, so your goods stay safe. You can also use things like anti-slip paper or rubber mats for extra safety, but dunnage bags work best for stopping movement.

Using dunnage bags lowers the chance of accidents, damage, and delays. You make sure your cargo gets there just like it left, which is the main goal of any cargo control system.

You can use dunnage air bags to keep cargo safe. First, look at your cargo’s size, shape, and weight. This helps you pick the right dunnage bag and valve. Next, choose a bag material that fits your shipping needs. Think about temperature or humidity. Clean the inside of your container and take out sharp things. Get your inflation tool and valve adapter ready.

Here are the steps for using dunnage air bags:

Put dunnage air bags in the spaces between cargo. Do not put two bags together, or they might break.

Fill each bag with air until it is about 80% full. This helps the bag fit around your cargo.

Add more air until the bag feels firm. Then close the valve tightly.

Check for leaks and make sure nothing heavy sits on the bag or valve.

The right air pressure depends on the bag you use. Lighter bags need about 2–3 PSI. Stronger bags may need up to 6 PSI. Some jobs need as much as 90 PSI. Always follow what the maker says.

Dunnage air bags have tough paper or woven layers. Inside, there is a part you fill with air. When you blow them up, they fill empty spaces and hold cargo still. These bags soak up bumps and cut down shaking during travel. The air inside acts like a soft pillow to protect your goods. The outside layers help stop cargo from sliding. Dunnage bags work better than wood or foam blocks.

Dunnage bags hold loads in place and stop them from moving.

The air inside softens impacts and keeps cargo safe.

You can use them in trucks, railcars, or shipping containers.

You can use dunnage bags in many ways. In trucks, paper dunnage bags are good for fast loading and unloading. Railcars often use polywoven dunnage bags for long trips and hard bumps. For sea containers, polywoven or vinyl bags fight off water and protect against rough sea travel.

| Transportation Mode | Dunnage Bag Type | Key Application Features |

|---|---|---|

| Trucks | Paper dunnage bags | Fast to fill, low cost, great for pallets |

| Railcars | Polywoven dunnage bags | Strong, steady, best for long trips |

| Sea Containers | Polywoven or vinyl bags | Resist water, protect important goods |

Dunnage air bags are a simple and strong way to keep cargo safe in any kind of shipping.

You want your shipments to arrive with nothing missing. Dunnage bags help stop damage by keeping cargo steady. When you put dunnage bags between pallets or boxes, items do not slide or tip. This easy step helps you save money by stopping product loss. Dunnage bags keep loads from moving during shipping, so goods stay put. You can trust them to lower the chance of damage from shifting. If you use the right size and place them well, dunnage bags press just enough to hold the cargo. You can also put cardboard on both sides of the bags to keep products safe.

Dunnage bags do more than fill spaces. They protect cargo from being crushed and from getting wet. Here is how they help:

Dunnage bags fill gaps and change shape with temperature, keeping pressure steady.

They act like cushions and soak up bumps, even if packaging gets weak from heat.

Dunnage bags press evenly, so cargo does not slide, even when it is humid.

The wide, even pressure stops crushed boxes and keeps loads steady.

Polypropylene dunnage bags also keep out water. This helps cargo stay safe in damp or cold places. If you use dunnage bags with desiccant bags, you make a dry, safe space. This stops mold, rust, and damage to packaging. Using both is important for stopping damage, especially for things that need extra care.

You want your goods to get there safe and in good shape. Dunnage bags fill spaces between cargo and stop swaying or moving. They keep stacked pallets steady and stop them from tipping. Dunnage bags spread out pressure and soften bumps and shakes. This lowers the risk of damage and helps with safe delivery. Dunnage bags are light, strong, and save money. You can use them for many kinds of cargo, so they are a smart way to keep goods safe. When you use dunnage bags, you help make sure your shipments arrive safe and whole.

You want to spend less on shipping and keep cargo safe. Dunnage bags are cheaper than using wood or steel for support. You do not need to buy expensive timber or heavy frames. Dunnage bags are quick and easy to put in and take out. This means you pay less for workers’ time. Here are some ways dunnage bags help you save money:

They cost less and work faster than wooden bracing.

You need fewer workers, so labor costs go down.

They help stop cargo from getting damaged, so you file fewer insurance claims.

Dunnage bags make less trash, which is better for the earth and lowers disposal costs.

Their light weight means you pay less to ship them.

Dunnage bags help you load cargo faster and save money every time you ship.

You can use dunnage bags again if they are not broken. This makes them a good choice for your business. They may cost more at first than single-use items, but you save money over time. If you take care of them, dunnage bags can last for years. You do not have to pay to throw them away after each use. Many companies, like car makers, use reusable dunnage bags to save money and make less waste.

Reusable dunnage bags help you save money in the long run and are better for the planet.

Dunnage bags are lighter than wood or metal supports. You can move them easily, so loading and unloading is faster. They are made from strong materials like polypropylene or plastic. These materials do not get weak from water or chemicals. Dunnage bags work well in wet places where wood might rot. They keep their shape and strength, even when it is tough. Plastic dunnage bags also protect things like electronics or food from water better than wood.

Their light weight makes work easier for people.

Strong materials mean they work well in any weather.

Good for shipping near the ocean or in humid places.

When you pick dunnage bags, you get strong, reusable, and low-cost protection for your cargo.

Dunnage bags come in many strong materials. Each one works well for different shipping needs. Some common materials are:

Kraft paper

Vinyl

Polypropylene (woven and cladded)

Polyethylene (LLDPE, LDPE, HDPE)

Polyethylene terephthalate (PET)

Mylar®

Foil-lined polyethylene

Polyvinyl alcohol (PVA)

Woven polyester

These materials help dunnage bags last a long time. They can be used again and protect cargo during shipping. Dunnage bags also come in many sizes. The size you need depends on your cargo and the space to fill.

Pick small airbags for light or breakable cargo. These give soft support.

Use big, strong airbags for heavy or large shipments.

Always fill empty spaces so cargo does not move.

Choose standard or custom sizes for your cargo’s shape.

You want your shipment to be safe. Think about these things when picking a dunnage bag:

Good quality and careful making keep cargo safe.

Easy valves make filling and emptying simple. They also let you use the bag again.

Custom sizes fit your cargo just right.

Bags that handle hot or cold are important for some shipments.

Recyclable bags help the planet.

Tip: Make sure your dunnage bag can work in the coldest place your cargo will go, even as low as -30°C.

Follow these tips to get the best from your dunnage bags:

Plan how you load based on cargo and bag material.

Put heavy things on the bottom and lighter ones on top.

Use straps or bars to keep cargo extra safe.

Fill all empty spaces with dunnage bags or foam.

Stack items with the heaviest at the bottom.

Dunnage bags fill gaps and hold pallets still. They can lower damage claims by up to 80%. You also save time and use less packing. Always train your team, check bags during shipping, and think about the shipping conditions for the best results.

Dunnage bags are an easy way to keep cargo safe when moving it. They fill empty spaces and help stop things from getting damaged. Dunnage bags also take in bumps and keep items from shifting. Experts like that they are light, simple to use, and protect cargo well. Many companies have fewer insurance claims and better deliveries because of them.

To get the best results, pick the right dunnage bag for your cargo. Put it in the most important spots and fill it with enough air. Try using dunnage bags to keep your shipments safe and make shipping better today.

You can find dunnage bags made from kraft paper, vinyl, or woven polypropylene. Each material offers strength and flexibility. Choose the right type based on your cargo and shipping needs.

Yes, you can reuse dunnage bags if they stay in good condition. Always check for leaks or damage before using them again. Reusing bags helps you save money and reduce waste.

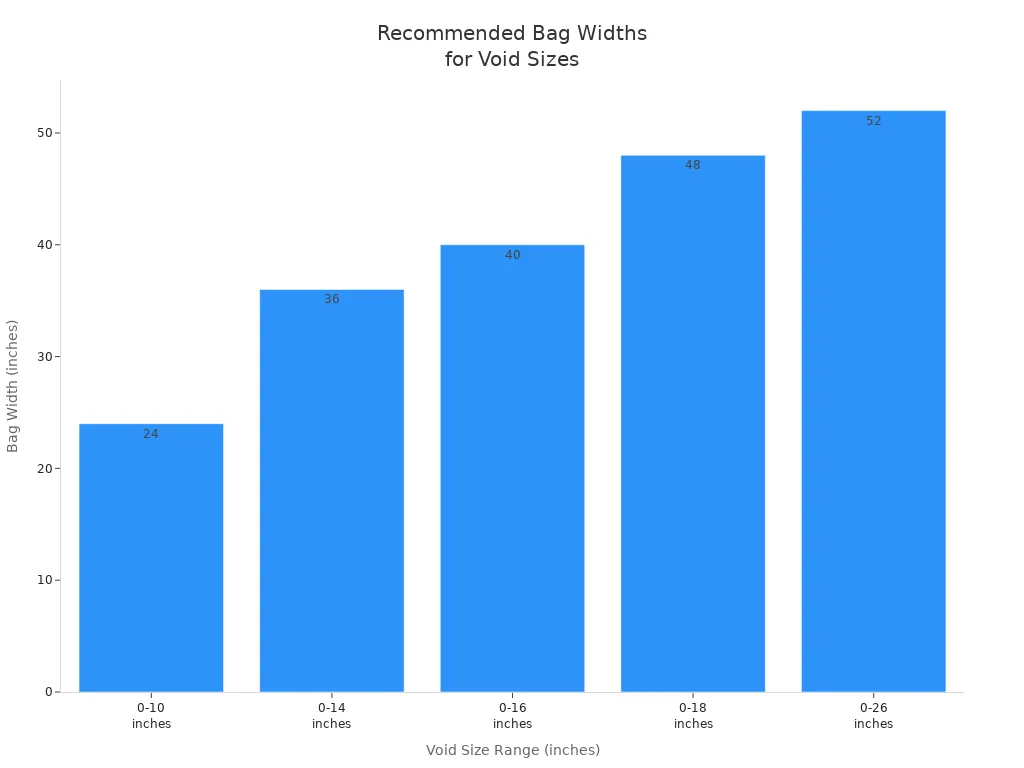

Measure the space between your cargo items. Pick a bag that fits snugly in that gap. If you use the right size, your cargo stays secure during transport.

You can use dunnage bags with most boxed, crated, or palletized goods. Avoid using them with sharp or pointed items that could puncture the bag.

Tip: Fill the bag until it feels firm but not hard. Most bags work best at 80% to 90% full. Always follow the manufacturer’s instructions for best results.